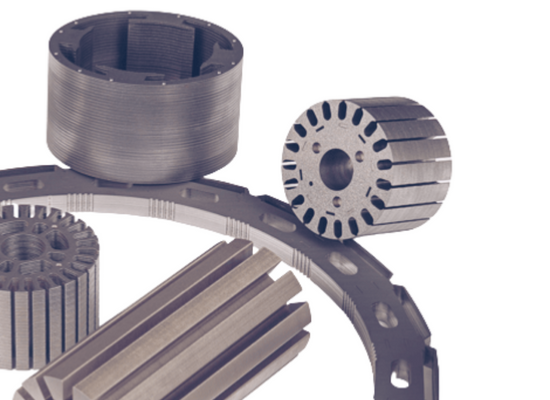

De la decoupe de precision à l'assemblageDécoupe de précisionSpécialisés dans la découpe de haute précision de tôles, nous fabriquons des rotors-stators, électro-aimants dipôles et quadripôles avec expertise.

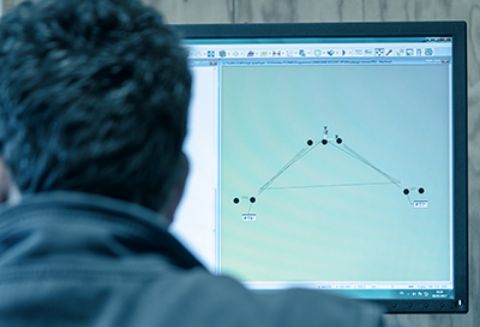

DécoupageNous étudions minutieusement votre demande de découpage pour vous proposer le processus optimal en fonction de la complexité, du type et du nombre de pièces souhaitées.

Emboutissage

Nous étudions avec attention votre demande d'emboutissage sur presses pour développer des processus et des outils de découpe de haute précision adaptés à votre projet.

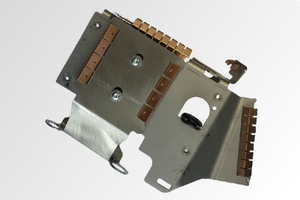

AssemblageNous vous proposons un service complet et de qualité, prenant en charge tous les parachèvements nécessaires, avec un atelier dédié au montage d'ensembles et de sous-ensembles.

Nos domaines d'application

Depuis 1977, notre expertise en découpage de précision et emboutissage de pièces industrielles a conquis de nombreux partenaires dans divers secteurs d'activité.

Nos métiers, notre savoir-faire

A propos Notre expertise et notre expérience nous permettent de fournir des solutions sur-mesure pour le découpage et l'emboutissage sur presse de vos pièces, quelles que soient les séries (petites, moyennes ou grandes). Chez OMEDEC, nous sommes à l'écoute de vos besoins et proposons des services complets allant de la conception d'outillages de découpe au parachèvement, au conditionnement et au montage d'ensembles et de sous-ensembles. Nous sommes fiers de collaborer avec des partenaires des secteurs industriels, médicaux et de la recherche, et de contribuer à la réalisation de tous leurs projets. pour les travaux de découpe Notre fierté : le barbecue vertical BioGrill, résultat de notre savoir-faireDepuis 2002, OMEDEC, expert en découpe et emboutissage de métaux, a développé sa propre marque de barbecues verticaux : les barbecues BioGrill.

Tout au long de ces années, notre équipe s'est engagée à les concevoir, les améliorer et les perfectionner, afin de proposer la meilleure version du barbecue BioGrill.

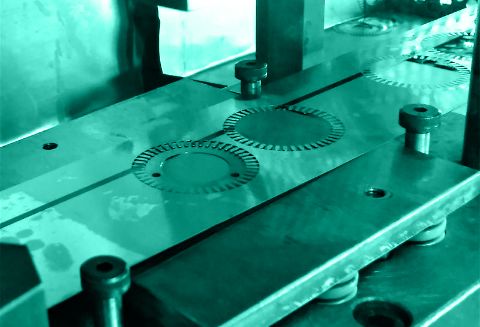

Grâce à notre savoir-faire, nous assurons une gestion complète, de la conception à la logistique, en passant par le prototypage, l'outillage, la découpe, l'assemblage des sous-ensembles et la commercialisation du produit. Notre expertise : la découpe de tôle électriqueOMEDEC s'est spécialisée au fil des années dans la découpe de tôle électrique. Nous sommes spécialisés dans la réalisation de tôles utilisées dans la conception d'électro-aimants dipôles et quadripôles, qui sont largement utilisés dans des domaines tels que la recherche (accélérateurs de particules) et le secteur médical (par exemple pour les équipements de protonthérapie).

Nous sommes également experts dans la découpe de rotors-stators, essentiels dans la fabrication de moteurs électriques. La découpe de ces pièces exige un savoir-faire et une grande précision (sans bavure et avec un jeu de découpe réduit) pour garantir des résultats optimaux. |